News

-

2024-07-08

2024-07-08Factors affecting the production efficiency of Three-Return Dryer:

There are many factors affecting the production efficiency of the three-return dryer, many such as the environmental impact of mechanical use, the use of components and the state of wear, etc., will reduce the use efficiency of the machine. During the work of the three-way dryer, each part is in a high temperature state, when the mortar and mineral powder enter the drying cylinder for drying, there will be a lot of steam discharged at the exhaust hole, for drying materials we need to do logistics support in each link, because there will be materials in the drying did not dry, need to return to the oven drying. Three return dryer energy measures: 1. Reduce heat loss 2. Reduce evaporation load 3. Increase the hot air temperature 4. Waste cycle 5. Air flow direction control 6. Exhaust air volume control 7. Drying solvent control 8. Automatic control 9. Waste gas heat recovery 10. The impact of three-return dryer installation and use 11. Impact of ambient humidity

-

2024-07-08

2024-07-08How to Reduce Noise in Triple Cylinder Drying Machine?

The three-return dryer and other dryers are medium and large machinery, and the three-return dryer produced by the old era and the undeveloped technology dryer manufacturers is noisy in the operation process. Now our country is advocating energy conservation and environmental protection, and the noise of the dryer also affects the lives of residents. In today’s advanced society, the noise problem of the three-trip dryer can be avoided, so how is it done? For you to analyze how the three-return dryer is able to reduce the noise problem: 1. Add sound insulation cover. The whole three-pass dryer is closed by using steel structure skeleton, thin steel plate as shell, internal damping layer and filling with ultra-fine glass wool or other sound absorbing materials. Because the three-return dryer generates a lot of heat when it is running, attention must be paid to solving the heat dissipation in the cover and facilitating equipment maintenance. 2. With rubber liner instead of manganese steel liner, the noise level can be reduced by 9dB(A), and the spectrum characteristics also have high frequency to low frequency. 3. Set the elastic layer. Lay a heat-resistant soft rubber pad between the inner surface of the three-return dryer drum...

-

2024-07-05

2024-07-05Which is more Advanced, Three Drum Dryer or Triple Cylinder Drying Machine?

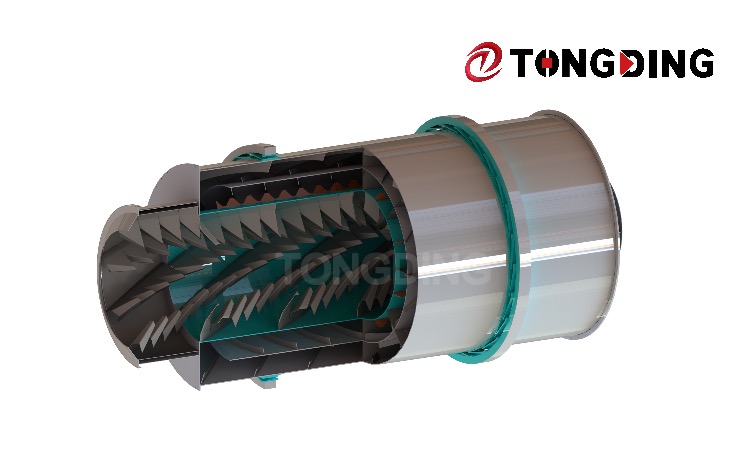

The two have similarities: 1. All industrial dryers are used to dry sand and other materials with good fluidity. 2. All are composed of three cylinders, and the material goes back and forth in the dryer three times to achieve full drying of the material. 3. Small floor area, high heat utilization rate, energy saving and environmental protection, dry thoroughly. The difference between the two: 1. Generally speaking, the three-return dryer is short in length and large in diameter, while the three-cylinder dryer is slightly longer in length and relatively small in diameter. 2. The three-cylinder dryer has no taper from the appearance, and is slightly longer, while the three-return dryer has a slight taper from the outside, and is thicker and shorter. 3. The three cylinders inside the three-return dryer have a certain taper, and the three cylinders inside the three-cylinder dryer have no taper. 4. Generally speaking, the length of the three-cylinder dryer can be designed to be longer, and the three-return dryer is designed to be shorter. Which of the two dries better? We suggest that it is better to use a three-cylinder dryer or multiple three-return dryers for drying materials above 50 tons per hour; The...

-

2024-07-05

2024-07-05What factors should be considered when using Sand Dryer?

1. Drying temperature: According to different materials, in the case of drying quality, try to choose a higher drying temperature to speed up the drying speed. 2. Humidity: Materials have different humidity. 3. Wind speed of hot air medium: The speed of hot air medium in the drying room is related to the drying speed, material shape and material characteristics. 4. Drying speed and drying method selection: drying should be controlled under technical parameters, such as temperature, humidity and wind speed, in order to achieve the retention of raw materials during the drying process. 5. Material placement: Stack thickness and placement method affect the drying speed. Reasonable control of pile thickness, increase heat exchange area and ventilation, speed up the drying speed. 6. Mixing and drying of different varieties: in principle, when raw materials are dried, a single variety is needed, and it is impossible to mix and dry together.

-

2024-07-04

2024-07-04What are the Advantages of the Non-gravity Twin Shaft Paddle Mixer?

Non-gravity twin shaft paddle mixer is widely used in dry mortar, chemical, pesticide, detergent, pigment food, monosodium glutamate, milk powder, salt, feed, chemicals, ceramics, plastics, rubber additives and other dry materials and mixing. How it works: The horizontal cylinder of the non-gravity twin shaft paddle mixer is equipped with a double-axis rotating reverse blade, which turns the material along the axial and radial circulation at a certain Angle, so that the material is quickly mixed evenly; In order to reduce the replacement cost of the wearing parts of the equipment, the blade blade can be made into two pieces, and a movable small blade is placed on the blade base to directly replace the worn small blade, which is economical and fast; The discharge form is generally pneumatic (manual) flap valve, arc valve is tightly embedded in the cylinder, flush with the inner wall of the cylinder, no material accumulation and mixing dead Angle phenomenon; The standard type has the difference of opening the door and opening the door to the side of the cylinder, and the material is clean and fast, and the residue is less. Performance characteristics: The rotation speed of the shaft driven by the reducer and...

-

2024-07-04

2024-07-04Precautions for installing Sand Tumble Dryer, do you need a Technician?

Sand tumble dryer is a kind of equipment for drying sand, minerals and other wet raw materials, widely used in more industries. Installation of sand tumble dryer need to pay attention to matters: 1. Select an installation site. When choosing an installation site, you should consider whether there is enough space and ventilation around the equipment. The equipment installation area should be flat and trouble-free to facilitate future equipment maintenance and troubleshooting. 2. Check the installation environment. Before installing the sand tumble dryer, check the site environment and ground conditions to ensure that the equipment can be installed on the ground smoothly, so as to avoid shaking and loosening during the operation of the equipment. 3. Ground the power supply. Before installing the sand tumble dryer, it is necessary to check whether the power supply meets the electrical requirements of the equipment. In addition, a grounding device must be installed around the device to avoid hazards such as electric shock or electric fire. 4. Disassemble the device. Remove the equipment from the container and assemble it according to the marks and drawings. Note the orientation and dimensions of the mounting components to ensure that the device is assembled correctly. 5....